Description

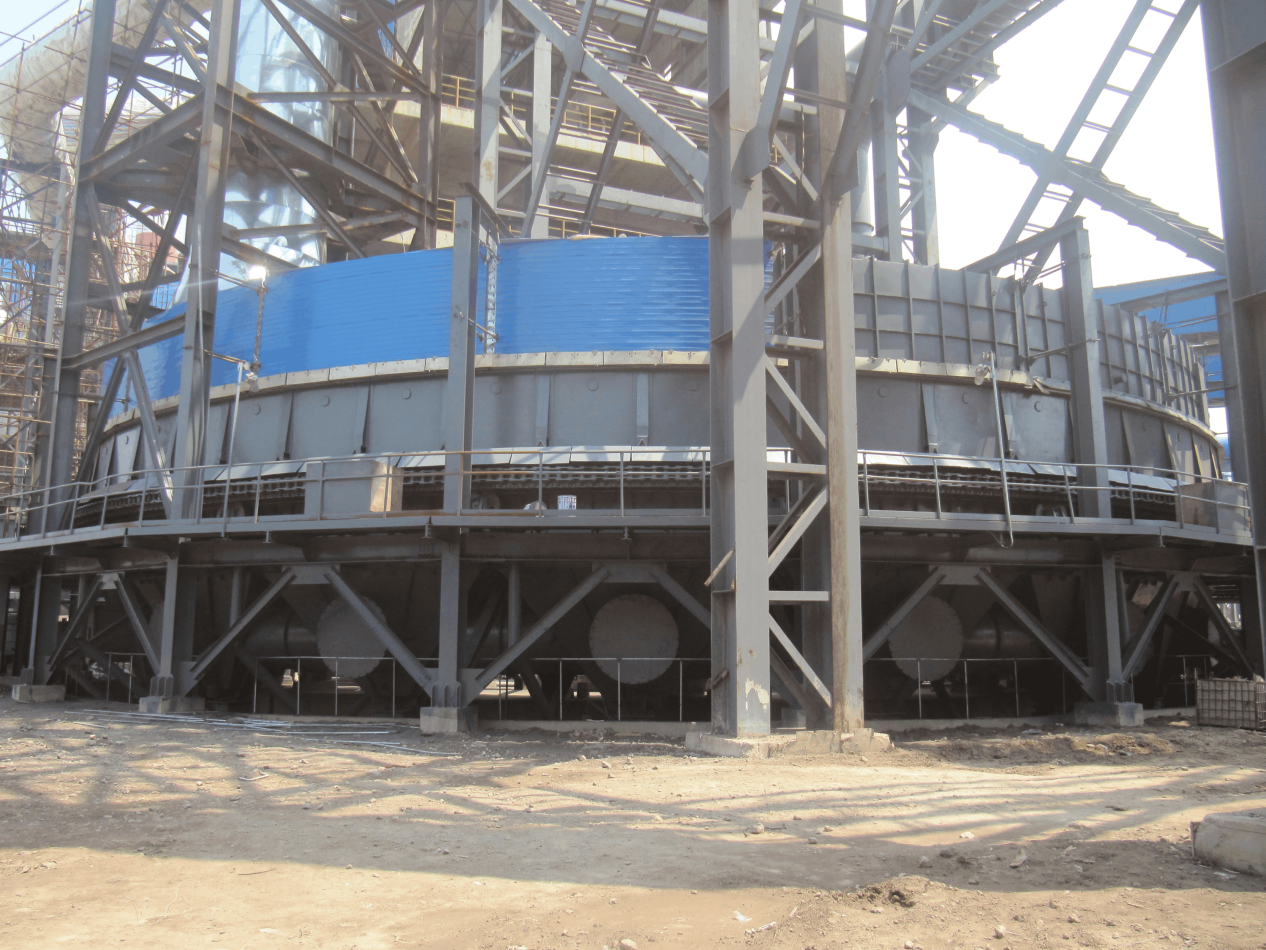

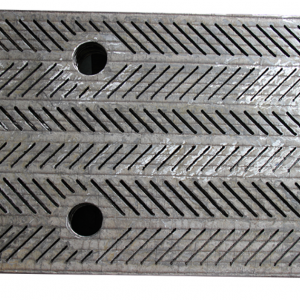

Annular Cooler is one of the main equipments in pelletizing process project, which is used for cooling the hot pellet from the rotary kiln, and also for absorbing the heat from the hot pellet, for reusing in the former process, to reduce the energy consumption of the whole process.

Technical parameter

| Specification | Model I | Model II | Model III |

| Effective cooling area | 69 | 121 | 150 |

| Pallet rotate mean diameter | Φ12.5 | Φ18.5 | Φ22 |

| Pallet quantity | 28 | 45 | 45 |

| Pallet Width | 2.2 | 2.5 | 2.5 |

| Material Thickness | 762 | 760 | 800 |

| Bellows | 9 | 15 | 16 |

| Double-layer Cinder valve | 9 | 15 | 16 |

| Capacity | 134~162 | 270~304 | 310~385 |

| Normal Cooling Time | 25.6~76.9 | 45 | 48 |

| Main Motor(frequency conversion) 2 sets | 11 | 15 | 15 |

| Rotate Speed | 320-970 | 320-970 | 320-970 |

| Spare Motor 2 sets | 2.2 | 2.2 | 2.2 |

| Rotate Speed | 1430 | 1430 | 1430 |

| Main reducer 2 sets | 315 | 315 | 315 |

| Primary reducer 2 sets | 1.5 | 1 | 1 |

| Auxiliary drive reducer 2 sets | 11 | 11 | 11 |

| 47297.25 | 40565 | 42052.5 |

Advantage:

- Compared with the traditional ring cooler, the power of the fan can be reduced by 40%-50%, and the air leakage rate can be reduced by 80%.

- Sintering plant daily maintenance and regular maintenance workload is reduced.

- Good sealing device reduces environmental pollution and improves working conditions.

Reviews

There are no reviews yet.