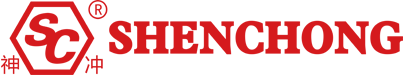

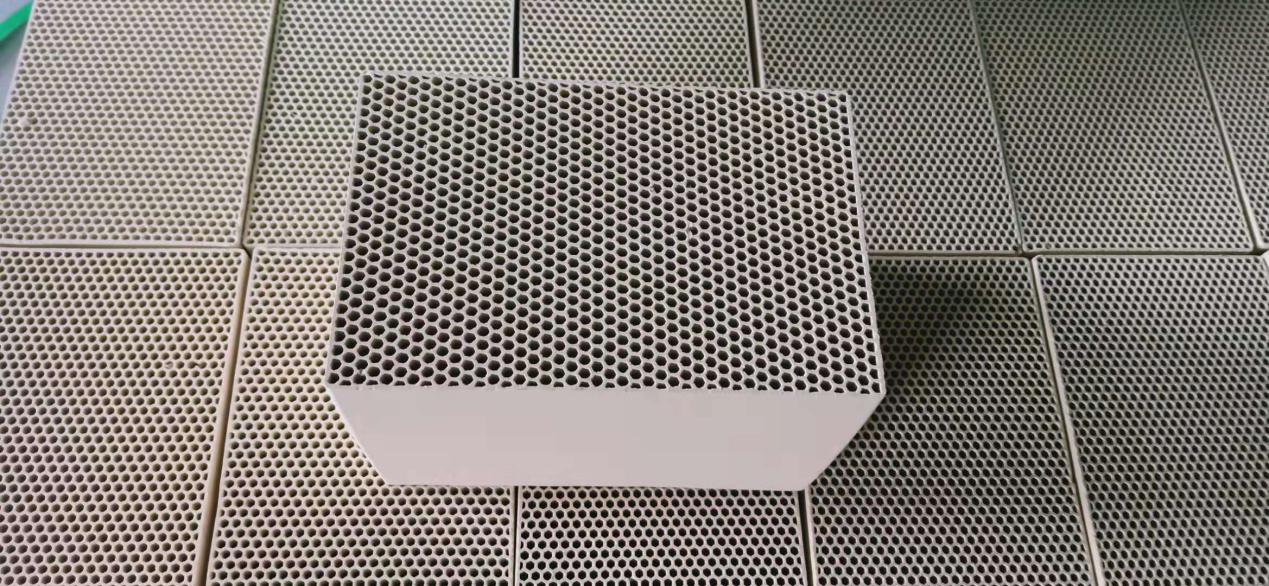

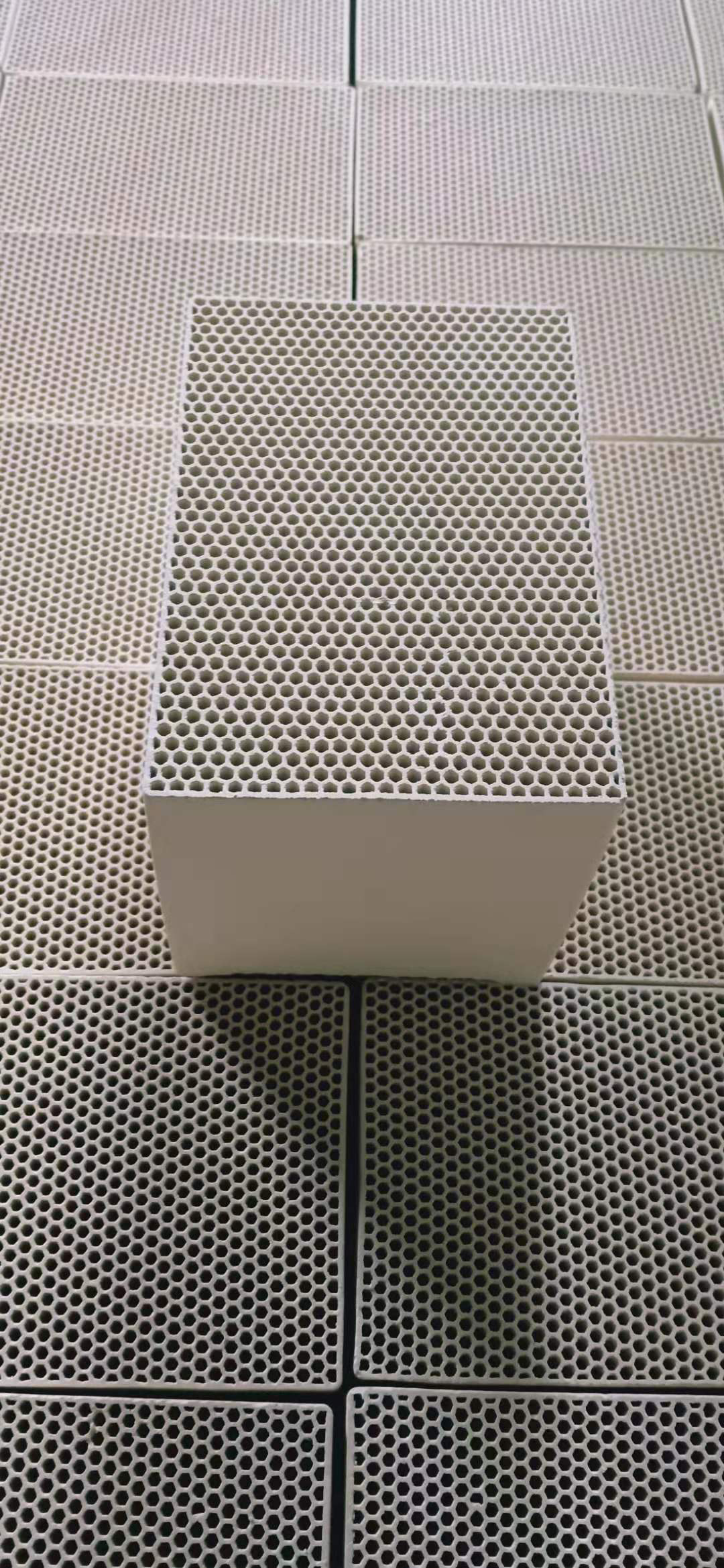

Brick

honeycomb ceramic, honeycomb brick,refractory brick,burner block,alumina brick

Description

Regenerative high-temperature combustion technology is a new concept of combustion technology, which organically combines the recovery of flue gas waste heat with efficient combustion and reducing NOx emissions, thereby achieving the dual purpose of ultimate energy saving and extreme reduction of NOx emissions. The honeycomb ceramic regenerator, which is also a high-temperature combustion regenerator, is the key and core component of the regenerative high-temperature combustion technology.

Product Characteristics

1.Material

corundum-mullite, mullite-cordierite, cordierite, mullite, zirconium mullite, silicon carbide composite, etc.

2.Hole pattern

square, rectangular, round, triangular, hexagonal hole, etc.

3.Advantages

※ high temperature resistance,

※ corrosion resistance

※good thermal shock stability

※high strength

※large heat storage heat

※good thermal conductivity

※other significant advantages.

| chemical composition | cordierite | Dense cordierite | cordierite-mullite | mullite | Corundum mullite |

| SiO2% | 45-55 | 45-55 | 35-45 | 25-38 | 20-32 |

| Al2O3% | 30-38 | 33-43 | 40-50 | 50-65 | 65-73 |

| MgO% | 10-15 | 5-13 | 3-13 | ||

| K2O+Na2O3% | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Fe2O3% | <1.5 | <1.5 | <1.5 | <1.5 | <1.5 |

| Thermal expansion coefficient 10-6/K-1 | <2 | <4 | <4 | <5 | <7 |

| Specific heat capacity J/kg.K | 830-900 | 850-950 | 850-1000 | 900-1050 | 900-1100 |

| Operating temperature℃ | <1300 | <1300 | <1350 | <1450 | <1500 |

| PS: we can supply honeycomb regenerators of other materials and sizes according to the actual application and customer requirements | |||||

Reviews

There are no reviews yet.