Description

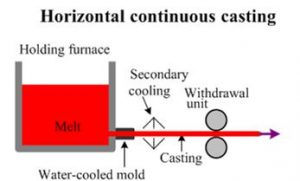

The continuous casting machine is composed by Middle tank, Crystallizer, vibration mechanism, dummy bar, secondary cooling channels, straightening and cutting machine.

At present casting machine used in industrial, according to the structure arrangement, it could be divided into following types:

1). Horizontal continuous casting machine.

2). Vertical (Vertical-bending)continuous casting machine.

3). Bending(Arc)continuous casting machine.

4). Centrifugal continuous casting machine.

Advantages of Horizontal Continuous Casting:

- Since the equipment arranged horizontally, body low can be installed in the existing plant, the low capital investment.

- High quality of cast strands. Since the tundish the crystalliser is directly connected, to prevent the secondary oxidation and inclusions in molten steel is easy to float in the middle of the pack, improve steel cleanliness. Especially suitable for high alloy steel casting.

- It can be directly cast into a small cast slab (e.g. 70mm billet), and even a few millimeters of wire rod, it can be made a minimum of rolling over the end product, greatly reducing the metallurgical production processes.

- Good security and reliability, due to the level of equipment arrangement, once the breakout burning fewer for subsequent equipment, and in Horizontal Continuous Casting and have a special monitoring device breakouts breakouts can be monitored.

At present, Horizontal continuous casting furnace is suitable for small and medium steel mills and the production of small cross-section to match the cast slab.

Reviews

There are no reviews yet.