Description

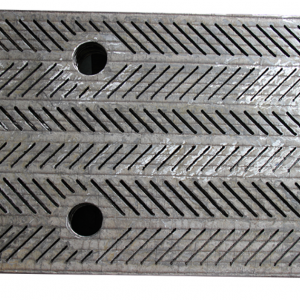

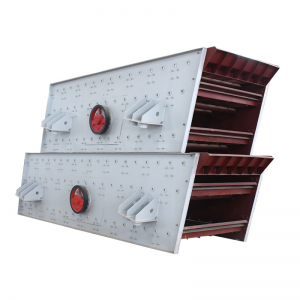

The key element for incinerators Boiler/Sinter Machine is grate bar. The grate system can be composed of moving grate bars and fixing grate bars. The structure and shape of the two grate bars are designed to be same so that it is very convenient for replacement. The width of grate system will be decided by handling capacity of waste. When calorific value is designed to be 6270kJ/kg, the surface temperature of grate bars is 400~500 centi-degree, the service life of grate bars can be about 5 years.

Technical parameter

| Material | Cast iron, Cast steel or appointed |

| Heating resistant | 550-1200 Degree |

| Size | Customzied design |

| Course of production | Model making→Molding→Mold assembling→ Material analysis → Melting→Pouring→Opening→Cleaning → Finishing→Inspection and Testing |

| Inspection | Chemical Composition Analysis, Dimension Inspection ,Tensile strength Test, Hardness Test. |

Advantage:

- It has high temperature oxidation resistance, high temperature strength, high temperature creep performance and room temperature impact toughness, which significantly improves the service life of grate;

- It can not only ensure the running stability of sintering machine, but also improve the utilization rate and working efficiency of sintering machine;

- Energy saving and consumption reduction, conducive to reduce the sintering process labor intensity, improve the working environment;

- The technique of epc improves the production efficiency and reduces the production cost of grate.

Reviews

There are no reviews yet.