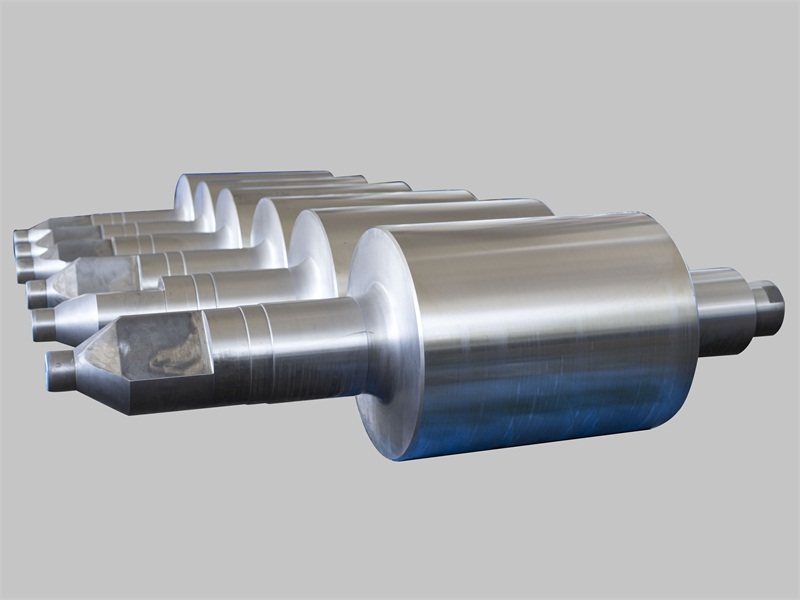

Stand roll

roller,carbide combination roll,AD140I roll,SGPI roll,SGAI roll,HSS roll,centrifugal casting roll, finishing mill roll,intermediate mill roll,roughing mill roll

Description

Rollers are the main working parts and tools that cause continuous plastic deformation of the metal on the rolling mill. They can be arranged in the form of two-roll, three-roll, four-roll or multi-roll in the rolling mill frame, and are composed of the roll body, roll neck and shaft head. . The middle part of the roll that actually participates in rolling the metal is the roll body, with a smooth cylindrical or grooved surface on the surface. The roll neck installed in the bearing transmits the rolling force to the stand through the bearing housing and the pressing device. The shaft head is connected to the gear base through the connecting shaft, and transmits the rotating torque of the motor to the roller.

Types of rolls with the most exports and the technical details are following:

| Grade | Drg | Size | Hardness | C % | Mn% | Si% | S% | Ni% | Cr% | Mo% | UTS (Mpa) | |

| Shore-C | ||||||||||||

| AD140I (Static Casting) | DE72ZG1. 6-5 REV.A | 610/520x760x1916mm | Barrel Hardness (HSD) | 45-55 HSD | 1.3–1.5 | 0.7–1.1 | 0.3–0.6 | ≤0.05 | 0.5–1.1 | 0.8–1.2 | 0.2–0.6 | 500-800 Mpa |

| Journal Hardness (HSD) | 35-45 HSD | |||||||||||

| Tensile Strength | 500-800 Mpa | |||||||||||

| Weight(kg) | 2158kg | |||||||||||

| SGPI | DE72ZG1. 6-4 REV.A | 480/420x700x1722mm | Barrel Hardness (HSD) | 50-65 HSD | 2.9–3.6 | 0.4–1.0 | 1.2–2.0 | ≤0.05 | 2.0–2.5 | 0.2–1.0 | 0.2–0.8 | ≥350 Mpa |

| Journal Hardness (HSD) | 35-45 HSD | |||||||||||

| Tensile Strength | ≥350 Mpa | |||||||||||

| Weight(kg) | 1254kg | |||||||||||

| SGAI | DE72ZG1. 6-2 REV.A | 380/320x650x1505mm | Barrel Hardness (HSD) | 68-75 HSD | 2.9–3.6 | 0.2–0.8 | 1.2–2.2 | ≤0.05 | 3.0–3.5 | 0.2–1.0 | 0.5–1.0 | ≥350 Mpa |

| Journal Hardness (HSD) | 35-45 HSD | |||||||||||

| Tensile Strength | ≥350 Mpa | |||||||||||

| Weight(kg) | 720kg | |||||||||||

Reviews

There are no reviews yet.