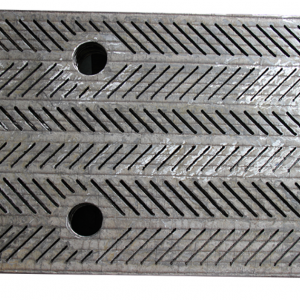

Description

Vibration exciter is a device attached to certain machinery and equipment to generate excitation force, and is an important part of using mechanical vibration. The vibration exciter can make the excited object obtain a certain form and magnitude of vibration, so as to perform vibration and strength test on the object, or to calibrate the vibration test instrument and sensor. The exciter can also be used as an excitation component to form a vibrating machine to realize the conveying, screening, compacting, shaping, and tamping of soil and sand.

Features

The exciter can generate unidirectional or multidirectional, harmonic or non-harmonic excitation force.

Typical modes common in actual engineering:

- Single axis vibration exciter and single arrangement

- Single arrangement of biaxial vibration exciter

- Series arrangement of dual-axis vibration exciters

- Two or three single-axis vibration exciters are arranged, running in the same direction but at different speeds.

- Multiple single-axis exciters (usually three) arranged to rotate in different directions

- Multiple single-axis exciters are arranged to rotate in the same direction

- Vertical vibration motor or exciter

- Three-dimensional vibration exciter

Classification

1.Inertial vibration exciter

Use the eccentric mass to rotate to generate the required excitation force. The unidirectional excitation force inertial vibration exciter is generally composed of two rotating shafts and a pair of gears with a speed ratio of 1. The two rotating shafts rotate in opposite directions at equal speed, and the two eccentric blocks on the shaft generate the resultant force of inertia in the Y direction. When working, fix the exciter on the excited part, and the excited part will obtain the required vibration. A self-synchronizing inertial vibration exciter is also widely used in vibration machinery. The two rotating shafts of this kind of vibration exciter are driven by two induction motors with similar characteristics, and do not use gears. The two rotating shafts with eccentric masses can realize constant speed and reverse rotation based on the principle of vibration synchronization, so as to obtain unidirectional excitation force.

- Electric vibration exciter

Pass the alternating current into the moving coil, so that the coil will vibrate under the action of electromagnetic excitation force in a given magnetic field. The constant magnetic field of the electric vibration exciter is generated by passing direct current into the excitation coil, and then passing the alternating current into the moving coil. The moving coil is subjected to periodic electromagnetic excitation force to drive the ejector rod to reciprocate. Contact the ejector pin with the excited part to obtain the expected vibration.

- Electromagnetic exciter

The cyclically varying current is input to the electromagnet coil, and a cyclically varying excitation force is generated between the excited part and the electromagnet. The electromagnetic exciter used in vibration machinery usually consists of an electromagnet core with a coil and an armature, and a spring is installed between the core and the armature. When AC power is input to the coil, or AC power plus DC power, or pulsating current after half-wave rectification, a cyclically varying excitation force can be generated. This kind of vibration exciter usually fixes the armature directly on the working part that needs to be vibrated.

- Electro-hydraulic vibration exciter

The hydraulic servo valve is driven by a low-power electric vibration exciter to control the hydraulic pressure medium in the pipeline, and a large excitation force is generated on the piston in the hydraulic cylinder, so that the excited part is vibrated.

NOTE: We can design and meet customers’ actual requirements.

Reviews

There are no reviews yet.